義大利威尼斯 Striatus 拱形3D混凝土列印砌體橋

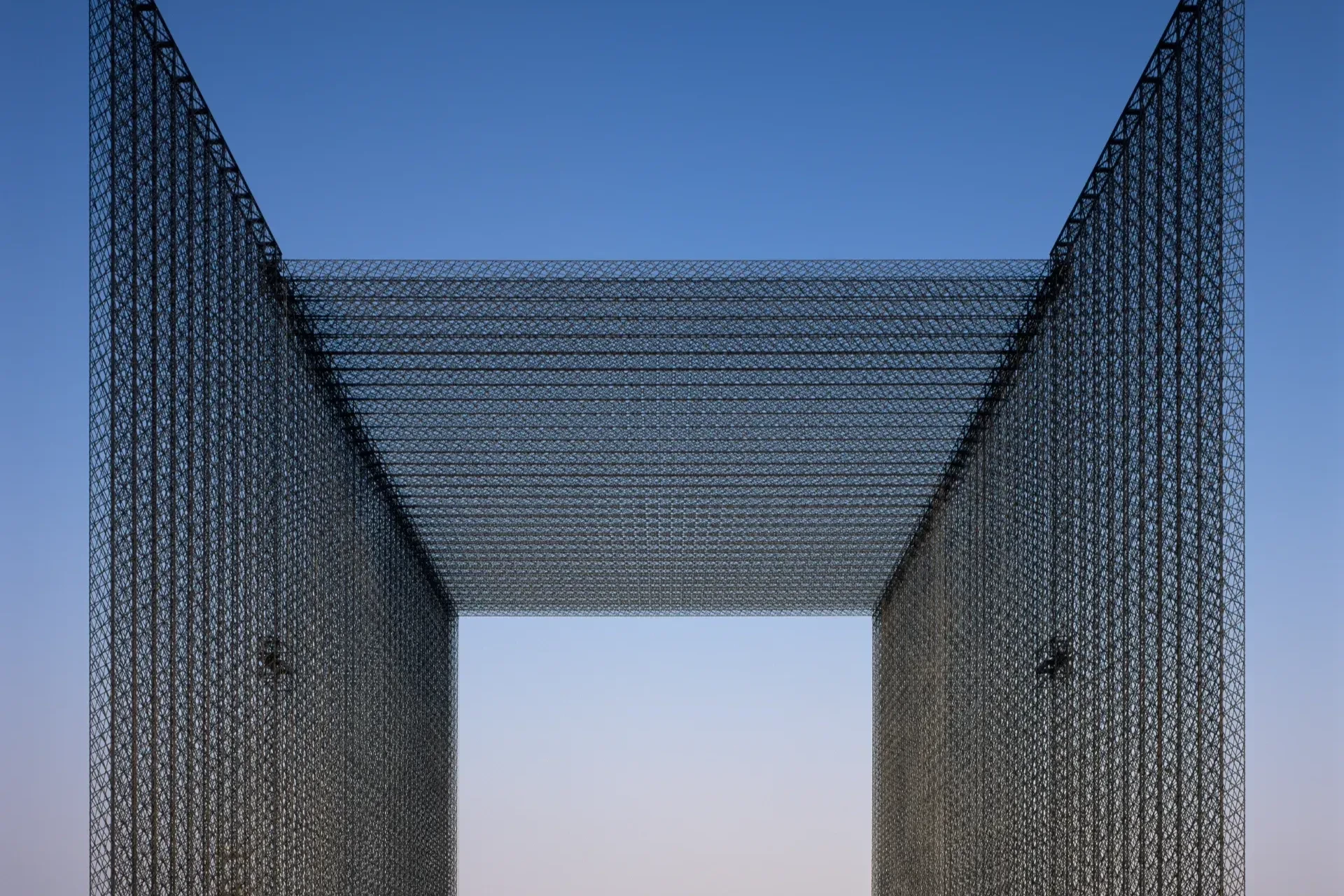

3D printing can be used to build load-bearing concrete structures that require significantly less material and no steel reinforcement or mortar. Zaha Hadid Architects Computation and Design Group (ZHACODE) collaborated with the Block Research Group at ETH Zurich and other partners from industry to present Striatus, an arched 3D-concrete-printed masonry bridge, proposing a new language for concrete that is structurally informed, fabrication aware, ecologically responsible and precisely placed to build more with less. Millions of new buildings all over the world are being constructed with reinforced concrete, even though this type of construction generates large amounts of CO2 emissions.

3D列印可用於建造承重的混凝土結構,這種結構需要的材料明顯較少且無需鋼筋或砂漿。札哈.哈蒂建築師事務所計算與設計團隊(ZHACODE)(Zaha Hadid Architects Computation and Design Group(ZHACODE))與蘇黎世聯邦理工學院(ETH Zurich)的塊研究團隊(Block Research Group)和其他行業合作夥伴,展示了 Striatus,這是一座拱形3D混凝土列印砌體橋,為混凝土提出了一種新的語言,它在結構上知情、有製造意識、對生態負責,並且精確地以更少的錢建造更多的東西。 全世界數以百萬計的新建築都用鋼筋混凝土建造,儘管這種類型的建築會產生大量的二氧化碳排放。

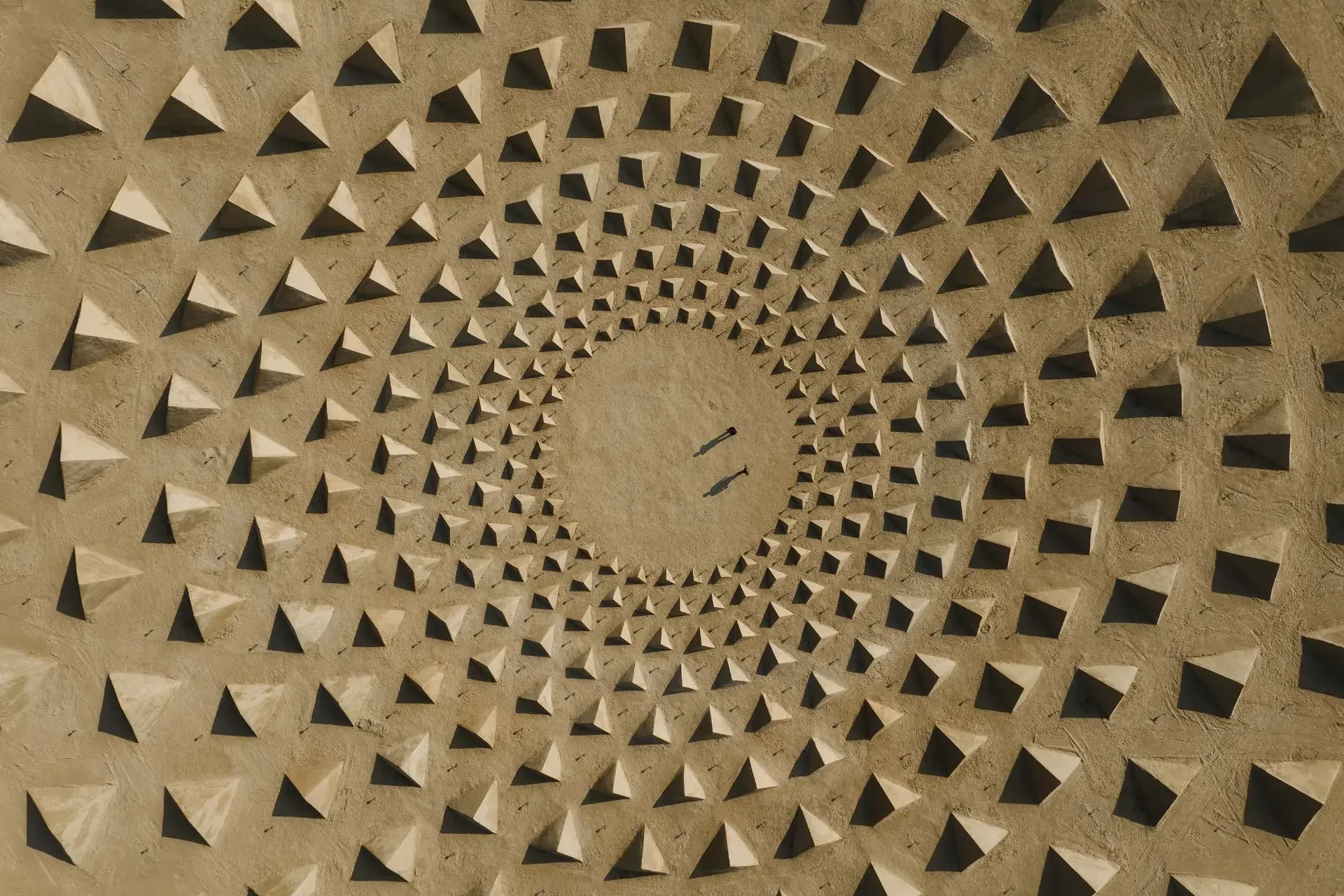

The steel used for the reinforcement and the cement for the concrete are especially problematic in this regard. The 3D printed concrete bridge – named Striatus - presents a way to reduce both. The 12-by-16-metre arched footbridge is built entirely without reinforcement, combining traditional techniques of master builders with advanced computational design, engineering and robotic manufacturing technologies. Using an additive process, the construction was built with concrete blocks that form an arch much like traditional masonry bridges. This compression-only structure allows the forces to travel to the footings, which are tied together on the ground. The dry-assembled construction is stable due to its geometry only. Because the construction does not need mortar, the blocks can be dismantled, and the bridge reassembled again at a different location. If the construction is no longer needed, the materials can simply be separated and recycled.

用於加固的鋼材和用於混凝土的水泥在這方面尤其成問題。名為Striatus的3D列印混凝土橋提供了一種減少兩者的方法。這座12×16公尺的拱形人行天橋完全沒有加固,將建築大師的傳統技術與先進的計算設計、工程和機器人製造技術相結合。使用添加法,該建築物是用混凝土砌塊建造的,這些砌塊形成了一個很像傳統磚石拱橋。這種只受壓的結構讓力量傳遞到地面,而地基是結合在一起的;乾式組裝結構因其只用幾何形狀而穩定。因為施工不需要灰漿,所以能將混凝土塊拆解,然後在不同的地方重新組裝橋樑;如果想拆除建物,材料也可以輕鬆地分解和回收。

Zaha Hadid Architects Computation and Design Group (ZHACODE) / Block Research Group (BRG) at ETH Zurich札哈.哈蒂建築師事務所計算與設計組 (ZHACODE) / 蘇黎世聯邦理工學院的塊研究團隊 (BRG)